What is Industrialized Construction?

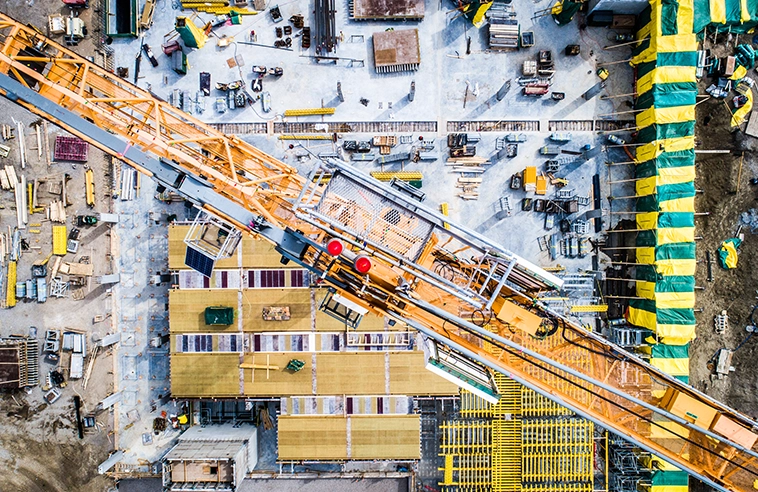

Amy Marks, the Head of Industrialized Construction at Autodesk, defines industrialized construction as: The application of manufacturing techniques to the built environment. Let’s explore this idea.

Industrialization is familiar when we think about the manufactured products that we have in our homes — from refrigerators to pencils. They’re made in factories and products of the same type are essentially the same. A particular model of Whirlpool fridge may have a few different options — black, white, or stainless steel; door opens on left or right — but otherwise all instances of that model are the same. We know that manufacturing hundreds, thousands, or millions of identical products leads to greater efficiencies for the manufacturer and, ultimately, lower prices for consumers. We also know that manufacturers of these kinds of products tend to automate some processes, reducing the human labor needed to create the products.

It’s important to note that industrialization is a matter of degree. As a process becomes more industrialized, it means it becomes:

- more repeatable

- more precise

- more automated

- less labor-intensive

- less skill-intensive

- faster

And, crucially, it results in essentially identical products each time the same process is executed. If a process is accurately replicated, but the resulting products differ widely, that’s a failed attempt at industrialization.

How does industrialization apply to construction?

Does industrialized construction mean 3D printing robots producing entire neighborhoods? Is industrialized construction the same as prefabrication in construction?

The answer to those last two questions is: no. Although robotics and prefabrication will tend to go along with greater industrialization of construction processes, they’re neither necessary nor sufficient for construction to become more industrialized.

Adding a robot, or performing a construction process under a roof, doesn’t automatically make a process more industrialized (although it does make it more likely that it is). And construction processes can become more industrialized with neither robots nor prefabrication.

That sounds weird, so let me explain. Although it’s correct that robotics don’t automatically mean a process is more industrialized, it does make it more likely — simply because it doesn’t make economic sense to use robots unless they’re making identical products with precisely repeatable processes. If a manufacturer has to program a robot each time they make a unique, custom product, then that’s not a very industrialized manufacturing process!

Prefabrication also doesn’t automatically mean that a construction process is industrialized. All it means is that construction (either of components such as panels and trusses, or of volumetric modules) takes place offsite, before it arrives at the construction site. But components or modules could be made entirely by hand, and to a completely unique, custom design — but under a roof.

So what does make construction more industrialized, if it’s not robots or prefabrication?

Amy Marks told me the key to industrialization in construction is thinking of buildings as products. (Of course, a building would be a product made of many other products. Just as a fridge is a product made of many components which are themselves products, such as condensers and screws.)

What does thinking of a building as a product really mean? Think of the difference between a hand-blown glass vase and a mass-produced glass vase you can buy from Wayfair. In each hand-blown vase crafted by an artist, you expect variations. In fact, the uniqueness of each piece is part of its appeal as a piece of art. But if you buy two of the same type of vases from Wayfair, you expect them to be pretty much identical. The process to make the mass-produced vase is repeated time and time again and the results are the same. When an artist makes a vase, each one is different. The artist’s process isn’t highly repeatable.

So if a building is a product, the idea is that it’s manufactured by repeatable processes — the more precisely repeatable a process is, the more industrialized that process is. And when those processes are repeated, the results are pretty much the same. (As with the color of a fridge, there can of course be superficial options, but these are kept to a minimum. The fundamentals of the building are the same.)

If a construction company builds custom homes, each one unique, the company is more like the glass artist than like the glass manufacturer. In contrast, if a construction company repeats the same processes and produces essentially identical buildings (or units of a building), then they’re more like the vase manufacturer. For example, a modular builder might manufacture identical modules, which can be used in many different buildings — especially for affordable housing.

In addition, a process becomes less labor-intensive and requires less skill as it becomes more industrialized. Hand-blowing glass vases is labor-intensive and requires great skill. One person can make only one vase at a time, and it’s difficult to learn how to do it. By comparison, operating a machine that manufactures glass vases is easy. (This video doesn’t show vase manufacturing, but it’s close: glass bottle manufacturing.)

Consider carpentry, for example. It usually requires a lot of skill. But if carpentry work is broken down into smaller, simpler tasks — each of which requires little skill — that’s a step towards industrialization. The shortage of skilled tradespeople, plus the housing shortage, is surely pushing the construction industry in this direction.

I expect we agree that there’ll always be a place for custom homes — the equivalent of a unique work of art. But what do you think about industrialized construction? Shouldn’t we also be making homes more like standardized products, just as we make fridges and mass-produced vases?

Learn more about industrialized construction

The 4 Dimensions of Industrialized Construction

The Power of Industrialized Construction (article and videos)

Industrialized Construction, Productization, and Transformation (video)

Leave a comment